Usually, there is no problem with removing a screw. A simple screwdriver and one anticlockwise rotation and the metal hardware are in your hand. However, if the screw is broken, the task becomes difficult, and the usage of the best screw extractor, a drill, or other special instruments becomes a necessity.

In most cases, the edges of the screws break due to the wearing out of the tool used. When the edges on the working area of the screwdriver’s blade are not sharp enough, and there is no tight contact between the blade and the screw, the destruction of the ribs on the screw head happens.

Another common reason for referring to the various methods on how to remove a broken screw is not strong enough intensity applied to the tool. Due to the fact that the screwdriver’s tip doesn’t fit snugly into the grooves on the screw head, the screwdriver’s tip slips during rotation, causing the edges on the screw to break.

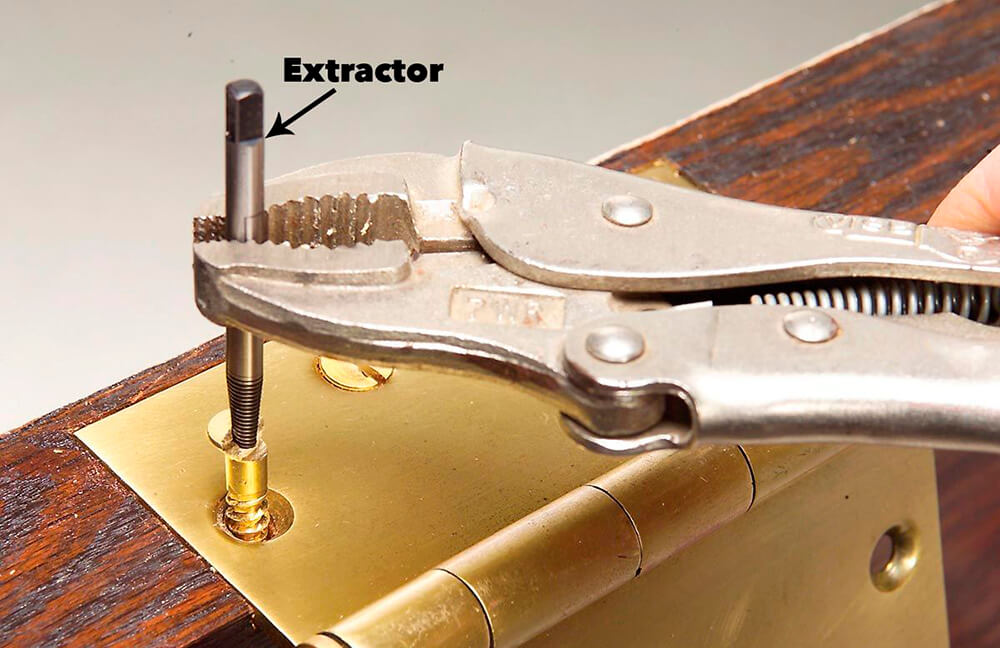

#1 Use the Extractor

Using the extractor is the most popular way of removing a broken screw, as this tool is aimed to deal with the most problematic cases. This is a special remedy for unscrewing the screws. During the anticlockwise rotation, it seizes the fasteners, preventing them from escaping. To remove broken screw with the extractor, you will need to drill a pit along the vertical axis, where the tool will be inserted. Note, that you need to choose a thin drill bit for this.

#2 Use The Pliers

If the screw part protrudes above the surface, you can try to grab it with pliers. Experts advise using thin pliers. Then, by turning it counter-clockwise, pull out the fastener.

#3 Use a Chisel

Nonetheless, if the screw has stuck deep, you will have nothing to take hold of. In this case, you will have to reach the zone into which the fastener is screwed.

If the screw is screwed into a block of wood, you can get close to it with a chisel. In the case of a concrete surface, you can superficially drill the surface near to a broken screw or make a cut down using a grinder to get an opportunity to grab the fastener with pliers.

If the screw is on the metal covering, it remains to make some additional holes nearby the screw in order to get close to it with the pliers.

#4 Deepen The Edges of The Screw

If the screw head broke off, you can cut new edges on the screw. In other words, to deepen the already existing edges that have been erased. The easiest option is to make one cut for a flat screwdriver. To do this, use the grinder or saw for metal.

#5 Use a Welding

Weld a nut, a rod, or some lever to a piece of a screw that will allow you to pull out the fastener without difficulty. You can use the method of cold welding, or simply weld a metal.

#6 Use a Soldering-Iron

If the broken screw got stuck in wooden material, it can be heated with a soldering iron. The metal will expand, and then will narrow again, the wood around it will be slightly burnt and the fastener will be pulled out much easier.