Your choice of drill press can be dependent on working with different materials. The crucial factors behind every purpose differ from one to another. You have to choose the wise one as per your work requirement to get the best results on your project. Moreover, depending on your choice the best drill press table can break or make the popularity for your work.

A model may be too powerful for your needs and, in this case, you pay too much. On the other hand, you may get a model that does not have too much power and you will not be able to get what you expect. Choosing the best drill press you need to carefully study what these machines can do and what options they have to get the model that will suit your needs perfectly. Here are some tips, which will help you understand how to choose a drill press. Consider the below-mentioned options while choosing or purchasing the drill press to work with accuracy and proficiency in projects.

Construction

With the advancement of technology, the drill press machine gets updated in the features to work on multiple purposes. The machine is now acting as one of the most versatile tools which get most sales on the market due to its efficiency. Primarily the machine is designed to work for the metalworking works as cutting tools, dividing the attached tools, Jigs, wood-related works.

Model

The primary thing to mind while purchasing the drill press is you have to be clear about the model variations and brand name. The distinguished model of the drill press is floor model and the bench top machines available mostly on top-branded materials. The floor-model machine is classic for heavy-duty projects and the workbench drill is optimal to use on small projects.

Features

When you plan to shop the drill press you should look on the features to match the efficiency and things how to select drill press related to your work. Depending on your work you have to insight the features from futuristic model machines. A depth stop on the drill machine matters to produce the depth of the hole. By knowing the depth stop you can get the idea to a made number of holes within the depth on the material.

Power

This parameter is very important. If you are going to work with tough materials and you need to drill deep holes, then you need a model with a powerful motor. If you want to work with wood, then you do not need a model that has a powerful motor installed. Some small models may have motors installed, which have less than one horsepower.

It is also necessary to pay attention to the depth potential – it shows how deep the hole can be made.

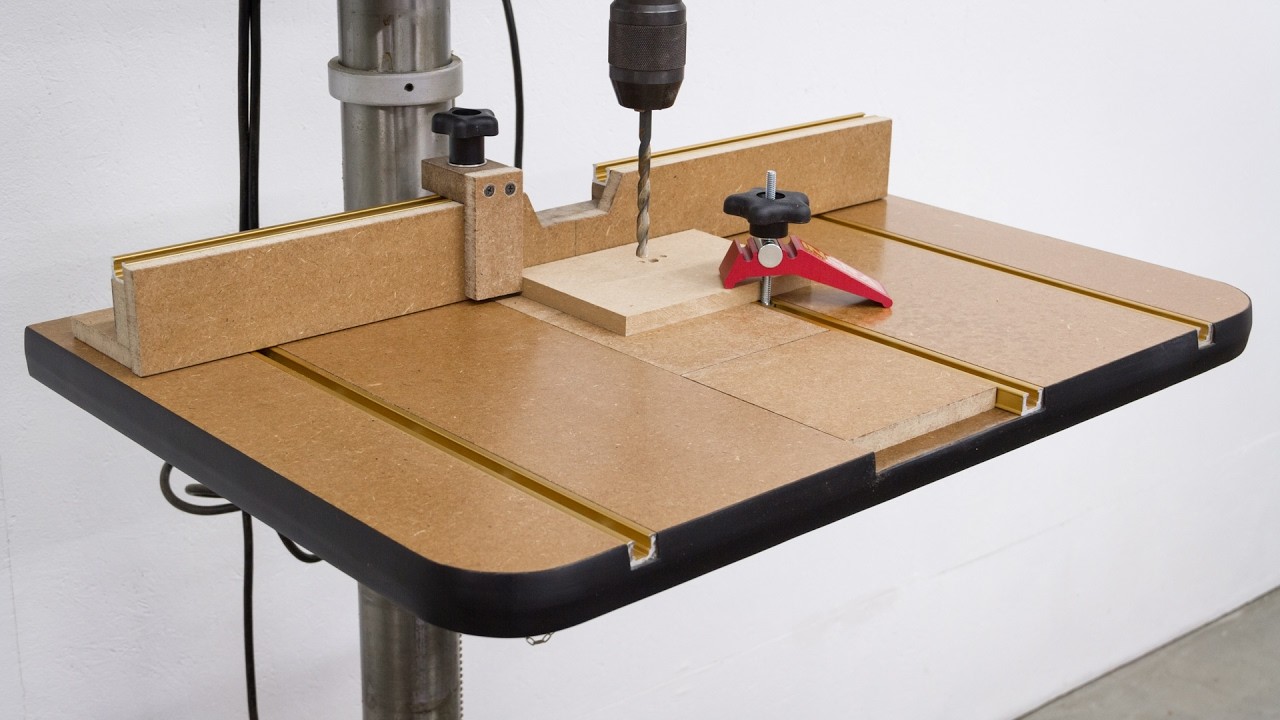

Quality of the attached table

The table in the machine is the base surface to carry the project materials. Check whether the table is in an adjusted type model or attached down, design of the table infrastructure and sizes. Updated drill press choosing tips is going with the swivel model. The strong substance gets drilled easier while using this drilling machine. Moreover, some tables can be rotated. It allows you working from any angle without using any additional accessories or tools. Such tables are made of durable material and they assure that the piece is sitting tight.

Portability

Keep in mind that you will work with a powerful tool that uses centrifugal force and it causes vibrations. When you drill something at high speed (especially if a model is very powerful) the vibration may lead to a disaster, like breaking a drilling bit or even a piece of material. Therefore, the powerful model has to be quite heavy. The weight will help to minimize or exclude vibrations completely. It allows you working smoother.

Weight of the machine is the main contributor which shows off the stability of machine. Bench top machines are mostly portable to move from one place to another. It is worth to invest in the drill press machine that has stability against vibrations while working. Look for the suitable accessories which are come along with the drill machine which is suitable for your purpose. Check out the plan on drill press machines from various brands and pick the wise one.

Capacity

One of the important drill press choosing tips involves determining how big the processed piece can be. The capacity is measured from the bore center to the column (where the motor is installed). This distance has to be multiplied by two. In other words, if you get an 18-inch model, then you will be able to make a hole located 9 inches from the piece edge. This distance (9 inches, in this case) is called the swing. Therefore, if you have an 18-inch piece, you can make a hole right in the center of it.

Various speed options

Modern models have variable speed options. This versatility is important since it allows you to process various types of materials. This is the case when you can get too much speed. For example, if you process a wood piece and the speed is too high, you burn the wood. High speed may also damage bits. Therefore, you should clearly understand what materials you want to process. Adjusting the speed, you make the motor belt move to other pulleys set, which are installed in the motor housing. Keep in mind that using high speed you increase productivity, but it also wears the tool faster.

Usually, people prefer to select models which can adjust the range within 500-4000 RPMs.

Serviceability

Any tool requires maintenance. Make sure the manufacturer offers any replacement parts you may need. Usually, the drill press maintenance process is fast and easy.