The coordinate table for the drilling machine helps make the work of the unit accurate, smoothly move the workpiece to the desired position, avoid jumps, and twist the part. The efficiency of work on any type of machine increases significantly when using the best drill press table. But what is actually the best? Let’s find out along with drill press table reviews.

Drill Press Table Reviews

WEN DPA2412T — Best Overall Drill Press Table and Fence

This potentially best x-y table for drill press was properly wrapped in close-fitting foam, and it came with no damage or missing parts.

If you are mechanically minded, you do not need instructions. The machine has been partially assembled in a very clever manner, and there is very little to do to complete a full assembly. It took me longer to modify a stand I had sitting around to mount the machine on than it did to set up this. From unboxing to plugged in and running was less than 45 minutes. Everything gathered flawlessly.

To test, I chucked up a ½-inch drill (it was new) and without a pilot hole, quickly drilled through a piece of ¼-inch steel angle and also through a scrap piece of ½-inch steel plate. There was no bogging or hesitation. I have drilled dozens of holes in steel, cast iron, and wood. I’ve used twist drills, countersinks, auger drills, paddle bits. This equipment is far from underpowered, and it completely outperforms any battery-powered hand drill. It’s obviously far easier to use for accurate drilling compared to a corded hand drill.

Pros

- It has ⅝-inch Chucking.

- The supplied clamps feel secure.

- The Variable speed is superb.

Cons

- No spindle lock.

Video WEN DPA2412T

Proxxon 27100E — Best Milling Table for Drill Press

This is the best small X-Y table I’ve used, and I highly recommend it for any small work. The gibs are very tight and precise, and both axes move very smoothly with the traverse knobs.

The ways are protected from chips, the gibs are adjustable, and the scales on both knobs plus a linear scale on the X-table are adjustable for ease of use. I work with watches and small clocks, so this device is ideal for this purpose, and it’s currently mounted to a precision micro-drill-press (the Cameron 164).

I can precisely place any work item and hold it firmly for drilling. The graduated dials make positioning very easy and accurate. I am currently using this tool with the Proxxon 24260 precision vise and the Proxxon 24256 step clamps, both of which work well with it.

Previously, I had numerous cheap import X-Y tables that were essentially useless. Due to sloppiness, crude construction, or poor fit of components, this device is completely superior to all of them and totally out of their league. Note that I am not associated or affiliated with Proxxon in any way, I just appreciate a well-made tool, and I’m very pleased that Proxxon is able to offer these at such a reasonable price.

Pros

- This instrument is very precise and stiff, in my opinion. There is no backlash in the sliding wheels.

- It’s very easy to re-zero the slide travel indicators, and they are convenient.

Cons

- This is a SMALL X-Y table, it will not work well for large items, and you cannot put a massive milling machine vise on it.

- I wouldn’t recommend it for tool steel, stainless, or anything harder. It’s just too small and lightweight, and you’ll get too much vibration to get a smooth cut.

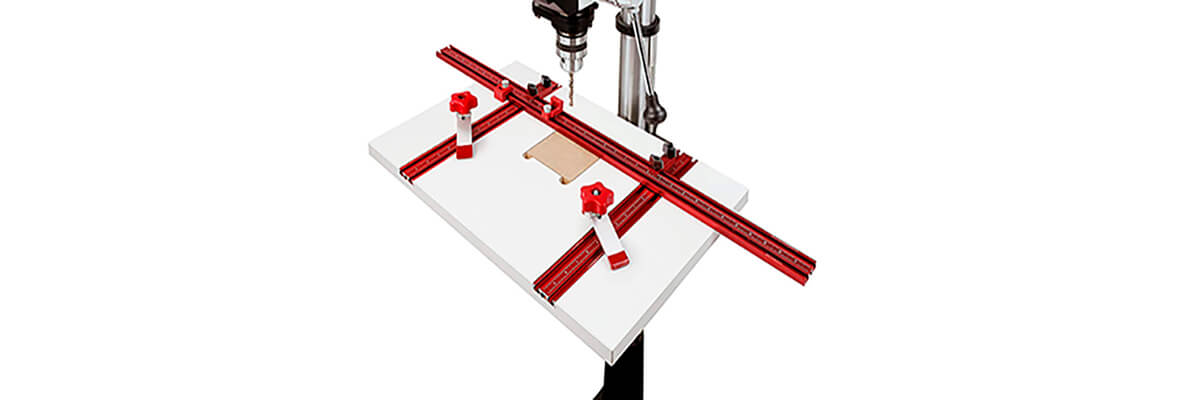

Woodpeckers WPDPPACK1

The moment you pull this thing out of the package, it screams quality. Some may say it’s ‘pricey’ but do the math and to buy everything it would cost the same or more if you made it yourself.

The installation for this is for ‘certain’ drill presses. Other’s require using a piece of plywood. In both cases, this results in the purchaser drilling holes and placing wood screws into the MDF material. Over time this will weaken the material where the screws will not hold, especially if you ever take the drill press table off.

The fact that no wood screws are used means that any clamping is very secure, and no wood screws will be pulled out of MDF. It can also be attached with wingnuts so the device can be removed if it is needed, and reattached in seconds. All you need to do is purchase more bolts, wingnuts, screws, and washers. If you have any skill at all, this should take no more than 1 hour to do. The completed item will take over 1000 pounds of force and nothing will pull out, or pull off. Perfect if you ever use this with a mortising attachment and clamp to this.

Pros

- The clamps supplied are excellent and effectively hold the item in place.

- It was easy to install, and I didn’t need to make any modifications to my drill press or the table.

Cons

- Only suitable for a 12-inch or larger press.

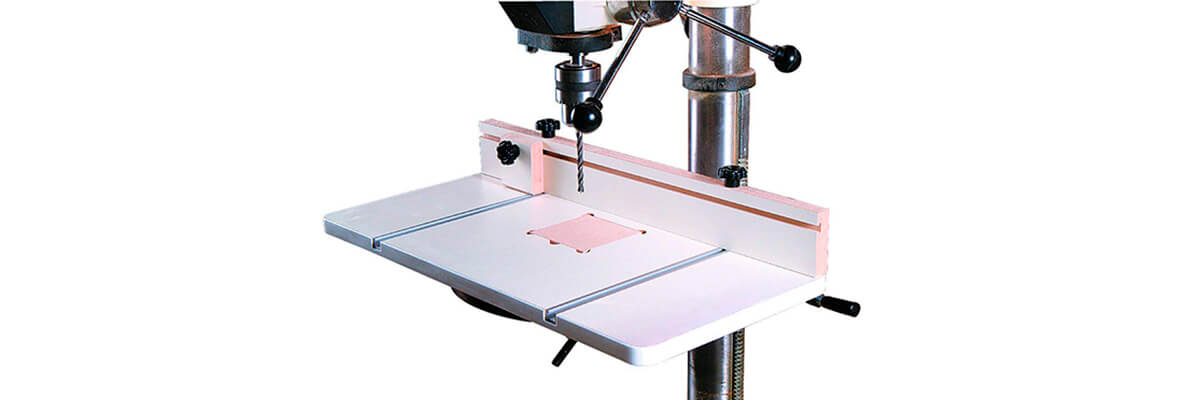

Woodpeckers WPDPPACK2

The 16 x 23 x 1-inch Woodpeckers drill press table is designed for drill presses from 12 inches. Its surface is covered with low-fraction MicroDot laminate with a matte finish. It handles glare perfectly to provide easy visual alignment. The table edges feature a durable high-density banding prominently bonded to the MDF core.

The unit comes with two embedded dual tracks. They are held together by eight bolts, which prevent the tracks from coming out. Each track has grade scales for precise fence positioning. They are legible and made by laser to avoid easing. The dual-track system includes two winding flip stops. They can be accurately positioned on the fence for quick multi-holed drilling of a workpiece.

A 36-inch long dual fence also has a scale, and it’s easy to use from both sides of the table. The fence brackets allow the fence to be adjusted from left to right or front to rear. Besides, the fence is adjustable from side to side to increase the stock’s length to a full 28 inches. The press table also has two hold-down clamps with 9 slip tips to lock down material for heavy drilling operations.

Pros

- All of the pieces are very exact, making forging the device a breeze.

- The press table is compatible with the optional DP3 drop press fence to support stock on edge.

- The users don’t have to drill new holes since it is easily installed by using plywood.

Cons

- The laminated coverage is not completely smooth but has small pockets that collect micro sawdust. So, it takes more time to clean the table’s surface.

- This model is incompatible with non-slotted tables.

Fulton

The Fulton drill press table top is notable for its adaptability, since it is compatible with all kinds of drill presses. It is designed for drum sanders up to 3 inches across. The unit has 15 x 24 inches in size. Its thickness is 1-3/8 inches that is more than many other tops can boast. Such thickness makes this item stable, wiping out all the possible vibrations.

It is made of alloy steel, having the MDF top and bottom. They are laminated to avoid deformation because of moisture. Besides, the laminated surface is easy to clean and provides the stock’s easy positioning.

The distance between the centers of T-tracks is 9 and 5/16 inches. Two distinct post knobs move freely along the T-tracks. This allows the user to find a suitable working area. The press table fits both slotted and non-slotted tables, using the included post-knobs or aluminum hold-downs respectively.

To allow the fence to move forward or backward or to remove it, unscrew the clamps on the right and left sides of the T-rack. The L fence is nearly 2 inches high from the bottom to its top. Its 4 holes allow adding a board to make the fence higher, if necessary.

Pros

- The press table’s bolts are heavy duty.

- Wood slides effortlessly while drilling.

Cons

- It would be a good touch to have the T-tracks ruled for measurement.

- The users will have to drill their own holes to attach the T-tracks.

MLCS 9765 — Best Overall Drill Press Table and Fence

It clamps great to my drill press, though I’m wondering if I should drill some holes to bolt it on. It was easy to install. The quality is reasonable for the price, and I enjoy the T-track.

Sometimes I had to use a shorter piece of wood for the fence because the knobs to put the drill down interfere with the fence, this would be true for any table with a fence.

I also made my own replacement inserts. The most difficult element was determining the proper thickness of MDF. You could also plan the wood to the right thickness if you had a planer. All in all, I’m happy with MLCS. They don’t charge a fortune for their products, but I consider them of high quality.

Pros

- There is no need for any extra adjustments.

- It also has the clamping capability to the drill plate.

Cons

- As the workpiece moved, it needed to be further fastened.

Buyers Guide

Features you Need to Consider Choosing a Drill Press Table

Important details taken into account when choosing this device include:

- Material manufactured by the machine, with the need to improve the performance of heavy equipment. The preference is given to models with cast beds that can withstand significant vibration. A table with a welded steel or aluminum base is sufficient for working with boring machines.

- The quality of grinding the working surface, directly affecting the accuracy of drilling — the existence or absence of a second layer of protection.

- Type of guides and drivers. With increased requirements for smoothness and accuracy of movement and drilling, preference is given to coordinate sites with sliding bearings (ball screw group), creating a minimum gap.

- The ability to control the CNC (relevant if the need for continuous processing of parts or with increased configuration complexity).

What is the Best Way to Install a Drill Press Table?

The key criteria for installing the table on a drilling or other equipment are the number of axes of movement, the dimensions of the coordinate platform made in the form of a plate, the type of feed drive, and the method of control (manual or automatic).

The parameters of the technical process are determined by all dimensional aspects, including the width and pitch of the grooves, while taking into consideration the state standards.