If you are one of those who like doing something on their own or you just want to provide different services that involve the processing of materials then the problem of finding the best mini lathe seems familiar to you. Modern models can be quite powerful, so you can do almost everything you need. However, to choose the best mini turning machine you need to check various models and compare their characteristics.

Before you consider buying this product, you should clearly understand when you are going to use it and necessary size. If you work with large and heavy pieces, then consider getting a heavier model, but if you work with something small, then a lighter tool would be handy.

A modern mini lathe machine can be powerful and versatile. It may have several speed options and can be digitally controlled, so it can be easy to set the necessary speed.

This article consists of reviews, which are focused on different models to help you find the best tool that will meet your requirements perfectly.

Mini Lathe Reviews

JET JWL-1221VS

Here’s the model that feels very sturdy. The bed, the tool support, and the tool support base are made of cast iron, while the headstock and the tailstock are made of cast iron and steel. The assembly process isn’t hard if you are an experienced person. It is provided with all the tools necessary to assemble the lathe and to get it working. However, if it’s your first turning machine, you can easily assembly it using a detailed user manual.

To be honest, I had some trouble with leg extension to set it to fit, but it may be true for this unit only. What I liked about this model is its nice small controlling panel. It has a speed dial and a small display (it is also used to display an error code) that shows the current RPM. There is a forward/reverse switch that controls spindle rotation direction and the good thing is that you can change it without turning off the tool. The on/off switch uses the safety key, which can be removed so that no outsiders can start the turning machine.

The swing over bed is 12.5 inches long and the swing over tool rest base is 9.45 inches long. The distance between spindle faces is 20.5 inches and the faceplate diameter is 3 inches. It’s quite good for such a tool.

The JET JWL-1221VS is quite versatile when it comes to speed. It has three ranges: 60-900, 110-1800, and 220-3600. It also has 24 indexing positions, so you can process strong materials without worrying about your tools.

Pros

- The drive belt is easy to move to change rotational speed ranges (the belt itself feels durable).

- It runs very smooth and it doesn’t produce too much noise.

Cons

- It’s quite heavy – the net weight is 121.25 lbs.

Delta Industrial 46-460

Delta Industrial has a 1 HP 1725 RPM motor. The swing capacity is 12-1/2 inch, but the extension bed increases the overall bed length to 42 inches, so you can work with some large pieces. This tool comes with all the additional tools you need to assemble and maintain the lathe. The assembly process doesn’t take much time (you can do it for less than 30 minutes).

This item is equipped with electronic variable speed control. The control knob is used to dial the speed up and down within the speed range. It has three-speed ranges – 250-750, 600-1800, and 1350-4000 RPM. The speed range can be changed by switching among three pulleys. It also has a 24-position index pin. It has a slide switch to change between forward and reverse turning. It uses the 1-inch drive spindle with 8 RH TPI thread. This tool is equipped with a manual reset circuit breaker. Therefore, if the turning machine is overloaded or it’s stood idle for a long period, the circuit breaker will shut off the tool. You will have to restart the tool if it happens, but it’s a good additional protection of the lathe.

It has a 3-inch faceplate and a 6 and 10-inch tool rests for tool supply. The item weight is 97 lbs only.

Pros

- The motor is powerful (and it runs smoothly) so you can process some heavy pieces.

- The centers are lined up perfectly right of the box.

- The on/off switch can be locked in the “Off” position with a padlock to prevent any unauthorized use.

Cons

- It doesn’t have a digital display to see the current speed, so you can hardly get the specific RPM. However, there is a speed chart.

Grizzly Industrial T25920

The Grizzly H8259 is powered by a 3/4 horsepower 650-3800 RPM one phase motor. The weight of this model is 80 lbs., while the dimensions are 33 x 12 x 18 inches. The footprint is 29.5 x 7.5 inches. The bed width is 9-1/2 inch and the faceplate size is 3 inches. The assembly process involves four stages only and it doesn’t take much time.

This model is durable, the bed construction is made of cast iron. The frame, headstock, and tailstock constructions are made of cast iron and steel.

The swing over bed is 12 inches, and the distance between centers is 18 inches. The swing over tool rest is 4.5 inches.

It uses the right-hand spindle type. The spindle size is 1 inch, while the bore is 0.394 inches.

It has 3 spindle speeds. Unfortunately, this model doesn’t have any electronic speed controlling, so you need to move the belt from one set of pulleys to another. Therefore, you need to turn off the lather to change the speed, which takes some time.

This model is provided with such accessories as live and spur center MT#2, a quill handwheel crank, 3mm, 6mm, and 8mm hex wrenches.

I would state that this model would be good for some small-scale projects (where you process some small or light pieces). It isn’t very powerful or difficult to operate.

Pros

- The motor works stable and smooth, so it doesn’t vibrate.

Cons

- The motor gets too hot in a very short period.

- The tailstock doesn’t lock down extremely tight.

Shop Fox W1704

This small metal lathe has a 1/3 horsepower universal-type motor installed. The motor speed range is from 700 to 3200 RPM. The SHOP FOX has a speed dial to change the RPM. It doesn’t have any display to show the exact RPM, so it’s hard to use when you need a specific RPM value.

The distance between centers takes 13 inches and the turning diameter is 8 inches. This model isn’t very powerful and the distance between centers isn’t large, so this model is good for processing some small pieces.

The spindle and tailstock taper is MT #1, while the spindle size is 3/4 inches x 16 TPI. I dare to say that this is the smallest lathe machine on this list weighing 45 lbs. only, while the product dimensions are 7.1 x 27.9 x 13.7 inches and the footprint is 23.5 x 5 inches.

The SHOP FOX W1704 is provided with the necessary accessories, which include spur and live centers, a faceplate, 4-1/4 inch tool rest, a 7-inch tool rest, and a knock-out tool.

The construction is made of cast iron, so this model will last long.

Pros

- The price is reasonable (around $195).

- It doesn’t have too much power, so it will stop before breaking a tool.

Cons

- The dead center and pen mandrel wouldn’t seat straight which caused everything to turn out of round.

- It may stop working at low speed.

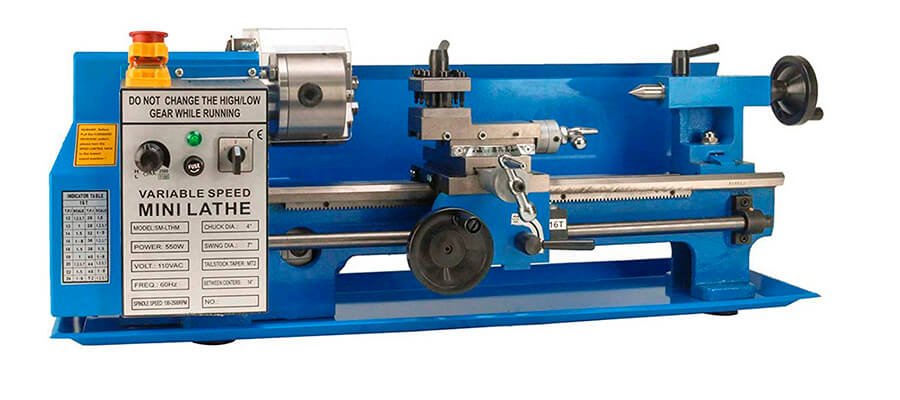

Erie Tools SP2102

This lathe features a single phase 400W, 0.53 HP motor. The motor speed is variable and it can be adjusted from 50 to 2500 RPM. The spindle accuracy is 0.0004 inches, while the thread range is 12 to 52 TPI. The distance between centers is 14 inches / 8 inches, so it is the model for not large pieces (considering its motor which isn’t very powerful). The swing over bed is 7 inches.

The spindle taper is MT3 and the tailstock taper is MT2, while the spindle bore is 0.79 inches and the chuck diameter is 4 inches. The cross slide travel is 2.56 inches and the top slide travel is 1.38 inches.

It seemed to me that the belt was too loose, and I had to adjust it before using high-speed settings.

The item weight is 104.2 lbs, while the package dimensions are 36 x 17.3 x 14.6 inches.

This lathe comes with accessories: an MT3 Spindle Taper, an MT2 Dead Center Tailstock Taper, a complete set of plastic change gears, and a 5-piece cutter kit.

Pros

- The motor works stable and the gearing is relatively quiet and smooth.

Cons

- It has some plastic gears which are not durable (it comes with a set of spare plastic gears, but you may run out of them very quickly).

- The manual isn’t detailed.

How to Use a Mini Lathe

Before you get your tool, you should know how to use it properly. It isn’t only about how to put a piece and process it, but it’s also important to know how to maintain a lathe to make sure it will work for years. First, you need to pay special attention to personal protective equipment like glasses and gloves. You should also have the first aid kit nearby. It is not recommended to wear clothing with long sleeves. Proper lighting is important as well – make sure you can see all the details.

Mounting a workpiece in chunks isn’t hard as you need to turn the spindle so the key faces up, then you should lock the spindle in the position. Place the chuck in position on the spindle. Then, engage the draw nut thread and tighten it. Rotate the spindle 180 degrees and engage the spanner wrench, then give four or five hammer blows to the wrench handle. Work automatically centers itself in the chuck, but you need to center it manually in the independent chuck. Mount the workpiece and tighten the jaws. Spin the workpiece manually and center it approximately, then tighten the jaws firmly.

Mounting work to faceplates is almost the same – check the accuracy of the faceplate with a dial indicator. I wouldn’t recommend using faceplates on different lathers as it wears faceplates excessively because truing cuts have to be repeated. You should mount the workpiece using T-bolts and the clamps of the appropriate size.

When you work on a hard piece or it is installed off-center you should use a counterweight to minimize vibration. Installing a piece you should make sure that it’s completely clean.

When you mount the work between centers you need to mount the piece in the universal or independent chuck and mount the center drill in the lathe tailstock.

Maintaining your lathe includes the cleaning stage – you should clean it after you used it. It’s necessary to wipe most of the grease using rags, and then you should clean the surface with paint thinner and coat the surfaces with oil. You shouldn’t forget about lubricating certain parts of the tool – check the manual to know what details should be lubricated and what type of lubrication should be used. Even the best mini metal lathe requires careful maintaining to serve you long.